Enhancing Powder Coating Sustainability: Effective Strategies for Optimizing Powder Recovery Efficiency

Powder coatings, known for their environmental benefits over traditional liquid coatings, offer sustainable alternatives due to their lower environmental impact and efficient resource utilization. Central

Optimizing Throughput: How Our Powder Coating Line Balances Speed and Quality

In the world of manufacturing, one of the biggest challenges we face is finding the perfect balance between fast production and top-notch quality. At our

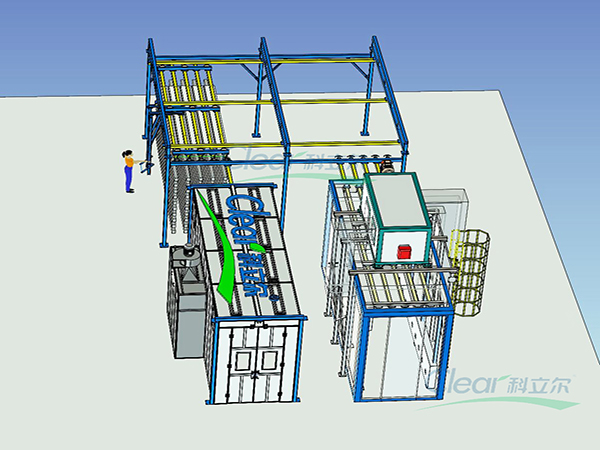

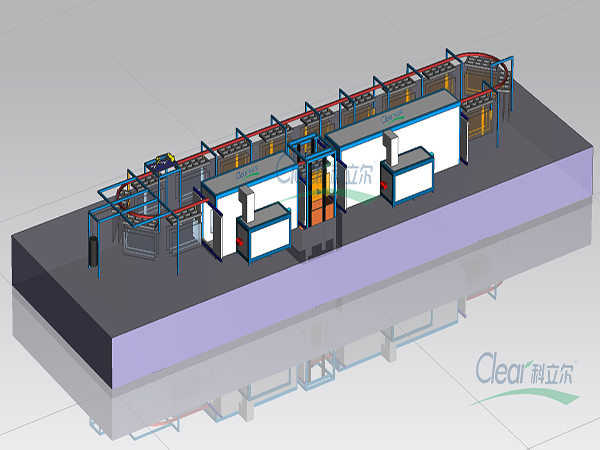

Manual Powder Coating Line

Powder Spraying Mode:

Manual or Semi-automatic or Automatic.

Conveyor Mode:

Manual or Semi-automatic or automatic.

Brief Introduction

Clear ® Manual Painting Line is a flexible system, which is suitable for coating large and small parts of different batches at the same time, equipped with a manual overhead conveyor which allows the transport of the parts to be treated along the entire production line.

1. Modular design allowing for most types industry, Easy to assemble and disassemble.

2. Flexible conveyor rail design, Different transportation systems can be equipped according to customer demand.

3. Safe structure and smooth operation of the system.

4:Curing ovens with electrical, oil fired & gas fired heating options are available.

5. We have experience in hundreds of installation projects around the world, engineers on-site service.

Clear® Manual Painting Line with local environmental protection requirements, ISO quality management system, CE quality certification. If you want to customize your machine. Welcome your inquiry.

Discover the Excellence of Our Manual Powder Coating Line

Discover the Excellence of Our Manual Powder Coating Line

At [Clear], we take pride in offering a Manual Powder Coating Line that stands out for its superior features and tailored solutions. Here’s why our line is your optimal choice:

1. Easy Assembly and Disassembly

2. Exceptional Flexibility

3. Advanced Design, Premium Quality

4. Durability and Reliability

5. Low-Maintenance Design

6. User-Friendly Operation

7. Efficient Cargo Handling Solutions

Offering You the Optimal Solution

At [Clear], we prioritize understanding your unique requirements:

Budget and Output: We tailor our solutions based on your budget constraints, daily output targets, and available manpower.

Workpiece Analysis: We meticulously analyze your painted workpieces, considering factors such as weight, size, shape, and other critical parameters.

Transport Track Design: Our experts craft a transport track design and configure data to ensure seamless integration and optimal performance.

Operation Mode: Choose between manual or semi-automatic operation modes, aligning with your production preferences and efficiency goals.

Experience the efficiency, reliability, and flexibility of our Manual Powder Coating Line tailored to elevate your production capabilities. Contact us today to explore how we can optimize your powder coating processes!

Key attributes

Industry-specific attributes

Other attributes

Product descriptions from the supplier

Outside Size | 7000x6500x3500mm(LXWXH) |

Inner size | 6920x4000x2900mm(LXWXH) |

Wall panel | 2mm thick cold rolled steel sheet with powder coating |

Air Circulation System | 4 sets of 5.5kw 4-72-5A outlay motor fan. Each fan air flow capacity:7000m³/h Pressure is 2000Pa, speed is 2900r/min |

Powder recycling system | Filter system is filter cartridge box,4*5pcs on each side,total 20pcs, each filter size: 324*900mm, with 20pcs pulse shaking device. Air compressor pressure:0.6-0.8MPa,valve pressure:0.6Mpa. Finial powder recycling rate is 94% |

Sliding door | Two sets of sliding doors for closing the booth after the products go into the booth to avoid powder overflow,size: 3000*2760mm(W*H) |

Lighting System | Ceiling Light: 2*8 units 18w LED lights |

Total power | 22kw |

Inner size | 8000x2600x2900mm (LXWXH) |

Wall panel | 150mm thick rock wool steel board |

Door | 2 sets pass through type doors,size 3000*2695mm(W*H) |

Circulation fan | 1 set of 5.5 kw GCF-4-79 6C high-temperature fan,fan and burner box inner is 1.2 mm thick galvanized steel, out is also 150mm thick rock wool panel to keep heat |

Heating system | Riello RS34 LPG burner |

control System | Electric control box use electric control box,electric components use Schneider brand. |

Total power | 5.5kw |

C-type conveyor

1.Installation?

Deliver with detailed specification of installation and operation

2.Payment terms?

T/T,40% for deposit and the balance 60% before loading into containe