Published by Yantai Clear – A Premier Factory and International Exporter

Introduction

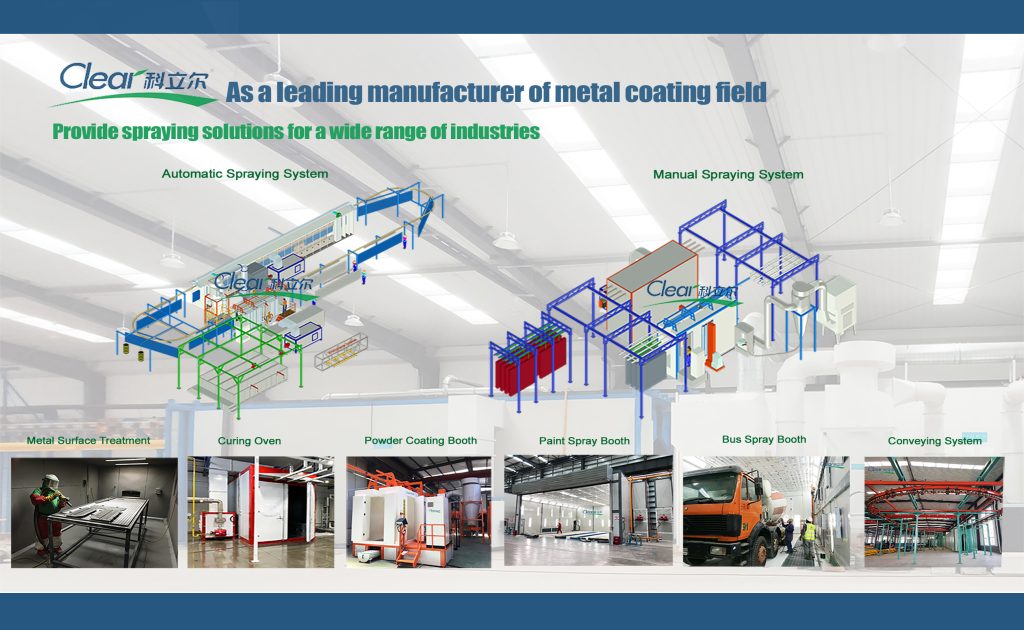

In today’s competitive manufacturing landscape, achieving a durable, high-quality finish is essential, regardless of the industry or product size. At Yantai Clear, we lead the way as both a factory and international exporter specializing in automated powder coating lines. Our cutting-edge systems cover the entire coating process—from meticulous surface preparation through powder application, oven curing, and final drying—ensuring a flawless finish on workpieces ranging from large structural components to tiny precision parts.

This article presents an in-depth look at our comprehensive powder coating process, detailing how every stage works in concert to deliver a robust, aesthetically pleasing finish. Our focus is on versatility, quality, and efficiency—elements that have enabled us to serve clients across diverse sectors, from automotive and construction to consumer electronics, furniture, and beyond.

1. The Comprehensive Powder Coating Process

Powder coating is a transformative finishing technique that converts raw or pre-treated surfaces into resilient works of art. Our automated powder coating lines are designed to handle any workpiece size or complexity, making them ideal for a broad spectrum of applications.

Surface Preparation: Laying the Foundation

Successful powder coating begins with a perfectly prepared surface. At Yantai Clear, we employ both chemical and mechanical cleaning processes tailored to each application. This ensures optimal adhesion for the powder layer and sets the stage for a high-quality finish.

– Chemical Treatment: We use specialized solutions to thoroughly clean surfaces and enhance their microstructure, improving powder adherence.

– Mechanical Processing: For larger or more challenging components, techniques such as abrasive blasting are used to remove residual oxides and create a textured surface that facilitates bonding.

– Eco-Friendly Practices: Our cleaning agents and procedures are selected for their low environmental impact, aligning with our commitment to sustainable manufacturing.

Powder Application: Achieving Uniform Coverage

Once the surface is ready, the workpiece enters the powder application stage. Our automated systems do not rely on robotic spraying, yet they achieve consistent and uniform powder distribution on both simple and complex geometries.

– Electrostatic Deposition: By applying an electrostatic charge to the powder particles, our systems ensure even coverage, whether coating a massive industrial panel or a delicate consumer product.

– Adaptive Process Control: Our lines are equipped with real-time sensors that automatically adjust voltage, spray pressure, and powder flow rate, tailoring the process to suit every specific substrate.

– Versatility for All Industries: From heavy industrial components to small decorative items, our powder application process ensures a smooth, consistent finish on every piece.

Oven Curing: Precision Heat Treatment

After powder application, the workpiece proceeds to the oven curing stage. This critical phase transforms the applied powder into a hard, durable coating through precise heat treatment.

– Exact Temperature Regulation: Our curing ovens maintain tightly controlled temperatures to ensure uniform cure without compromising the substrate’s integrity.

– Optimized Cycle Times: By fine-tuning curing durations, we achieve efficient throughput while maintaining high quality—a key advantage when managing production across various markets.

– Energy-Efficient Operation: Our ovens use advanced energy-saving technologies, which not only reduce operational costs but also support eco-friendly manufacturing practices.

Drying and Final Quality Control

The final drying phase removes any residual moisture or solvents, consolidating the robust, protective finish. At Yantai Clear, quality inspection is an integral part of our process to ensure that each product meets international standards.

– Advanced Drying Systems: Our controlled drying methods lock in the quality of the cured finish, eliminating common defects such as overspray and uneven gloss.

– Rigorous Quality Checks: Every workpiece is evaluated through multiple quality assurance tests—from thickness and adhesion measurements to visual inspections—ensuring each product achieves excellence.

2. Advantages of an Automated Powder Coating Line

Implementing an automated powder coating line offers a multitude of benefits that enhance production efficiency and product quality:

– Consistent Quality Across Varied Applications: Automation minimizes human error, ensuring even coating on everything from large structural components to intricate small parts.

– High Throughput and Efficiency: Standardizing each production phase increases output, enabling us to meet high-volume orders quickly without sacrificing quality.

– Cost-Effectiveness: Reduced labor and optimized material usage result in lower production costs, making our solutions competitive for clients across many industries.

– Sustainable Manufacturing: Energy-efficient systems and minimized waste contribute to an environmentally responsible production process.

3. Applications Across a Broad Spectrum of Industries

At Yantai Clear, the versatility of our powder coating lines is one of their greatest assets. Our technology is designed to meet the needs of clients from an array of sectors, proving that size or industry is no limitation.

– Automotive and Transportation: Enhance both the performance and appearance of vehicle components, from chassis parts to interior accessories.

– Construction and Infrastructure: Provide long-lasting protective coatings for architectural metalwork, bridges, and structural supports.

– Consumer Electronics and Appliances: Achieve smooth, decorative finishes on electronic housings and household products.

– Industrial Equipment and Machinery: Ensure durability and resistance to harsh environments for heavy-duty machinery components.

– Furniture and Decorative Items: Add aesthetic value and protection to metal furniture and design elements.

– General Manufacturing: Whether your work involves large industrial panels or small, finely detailed parts, our powder coating solutions are designed to deliver excellence across the board.

4. Yantai Clear: Pioneering Excellence in Powder Coating

At Yantai Clear, innovation, quality, and sustainability are the pillars of our operation. As a leading factory and international exporter, we are committed to pushing the boundaries of manufacturing technology and customer service.

– Commitment to Innovation: We continuously refine our processes by integrating the latest technological advances, ensuring that our powder coating lines remain at the cutting edge.

– Uncompromising Quality: Stringent quality assurance measures are embedded in every stage of production, guaranteeing products that meet and often exceed international standards.

– Customized Solutions: Understanding that each client’s needs are unique, we offer highly adaptable systems that can be tailored to specific production requirements.

– Global Reach: Our reputation as a trusted partner is built on decades of excellence in serving diverse markets around the world.

5. Embracing the Future: Digitalization and Sustainability in Powder Coating

The powder coating industry is evolving rapidly with the integration of digital technologies and sustainable practices. Yantai Clear is at the forefront of these trends, enhancing process control with digital monitoring and promoting greener production methods.

– Smart Process Monitoring: Real-time data collection and analytics allow for immediate adjustments, ensuring consistent, high-quality outcomes.

– Predictive Maintenance: Our advanced systems use data-driven insights to predict maintenance needs, reducing downtime and extending equipment lifespan.

– Eco-Friendly Innovations: From reducing powder waste to optimizing energy use, our focus on sustainable practices is integral to our process improvements.

Conclusion

The benefits of an automated powder coating line extend beyond mere efficiency and cost savings—they redefine production quality across industries. From thorough surface preparation to advanced curing and drying techniques, every stage is engineered to deliver a robust, visually appealing finish on workpieces of all sizes. At Yantai Clear, we take pride in offering a solution that caters to a diverse clientele, from large-scale industrial manufacturing to small-batch specialty production.

Our commitment to continuous innovation and quality assurance makes us a reliable partner for any business looking to enhance its coating processes. Contact Yantai Clear today to learn how our automated powder coating lines can transform your manufacturing operations and meet the demanding standards of today’s global markets.

—

At Yantai Clear, our passion for original, industry-leading solutions is reflected in every product we deliver. We invite you to experience the future of powder coating with our comprehensive, innovative systems designed for a world where quality and versatility matter above all.